Month: June 2025

Managing orders in a manufacturing plant can feel like a constant firefight. One day it’s a missed delivery, the next a production delay due to miscommunication or incorrect inventory updates. These issues stack up, leading…

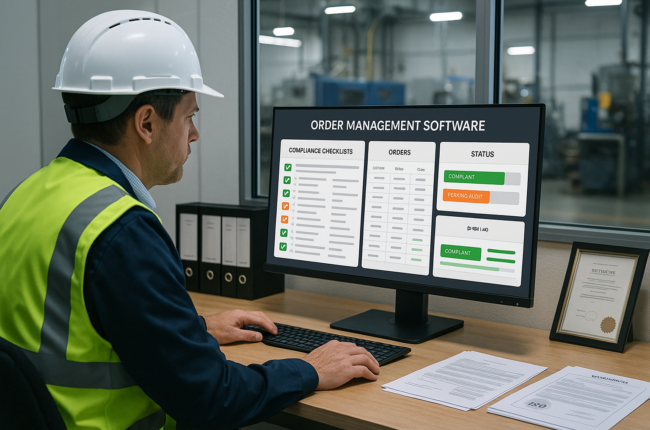

In today’s regulatory climate, manufacturers must be audit-ready at all times — not just during scheduled inspections. Whether it’s tax compliance, order documentation, or delivery traceability, being able to quickly retrieve accurate records is essential.…

Compliance in manufacturing is not just a requirement — it’s a necessity. Whether it’s tax regulations, quality standards, traceability rules, or industry-specific mandates, manufacturers must adhere to strict guidelines to avoid penalties and maintain trust.…

In a modern manufacturing setup, siloed departments are the biggest threat to operational efficiency. When sales, production, inventory, and logistics work in isolation, errors multiply, deadlines slip, and customers get frustrated. That’s why many manufacturers…

In an industry where speed and real-time decisions drive profitability, waiting to access production or order data from a desktop is no longer practical. That’s why many manufacturers are adopting mobile-enabled bulk order booking software…

Demand forecasting isn’t guesswork anymore — it’s a competitive advantage. With increased product diversity, tighter margins, and fluctuating customer preferences, manufacturers can’t afford to overproduce or understock. That’s why more production teams are now using…

In today’s manufacturing landscape, data is more than numbers — it’s the key to speed, accuracy, and profitability. Yet, many factories still make production and order decisions based on intuition or outdated spreadsheets. Smart manufacturers…

Manufacturers don’t all operate the same way — so why should they all use the same order booking system? From automotive parts to textiles, from multi-SKU production to custom project-based manufacturing, each business has different…