Author: Ripsil

In manufacturing, time is money. The longer it takes to fulfill an order, the more it costs your business — in inventory holding, labor, and lost customer trust. With rising demand and increasing competition, reducing…

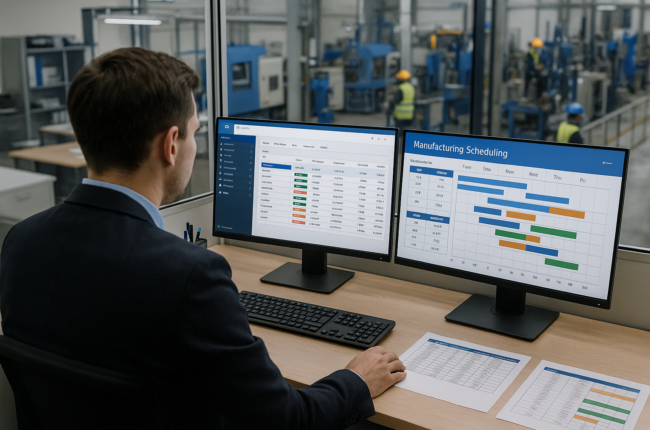

In today’s fast-paced manufacturing environment, delayed decisions and poor visibility can disrupt the entire supply chain. Lack of real-time updates often results in inventory issues, production bottlenecks, and frustrated customers. To solve this, manufacturers are…

In manufacturing, every minute counts — and so does every rupee. With growing order volumes and increasing complexity, relying on manual workflows can cost manufacturers more than just time. Many businesses are switching to bulk…

Modern manufacturing thrives on speed, accuracy, and visibility. But if you’re still managing orders through spreadsheets, emails, or fragmented software, you’re not just working slower — you’re risking costly errors. To stay competitive, more factories…

In today’s competitive manufacturing environment, speed and coordination are everything. Yet, many factories still use disconnected systems for order booking, inventory, production, and finance — causing duplication, delays, and avoidable errors. The solution? Seamless integration…

Manufacturing businesses grow — and with that growth comes larger, more complex orders. What worked for 50 orders a month no longer works for 500. As order volumes rise, the need for bulk order booking…

In manufacturing, timely delivery and order accuracy are non-negotiable. Customers expect updates, transparency, and seamless communication from the moment they place a bulk order. But without a proper system in place, errors pile up, communication…

Manufacturers often rely on long-term clients who place repeat orders at regular intervals. But without an organized system, recurring order management can become chaotic — missed quantities, incorrect dispatch timing, and duplicated entries are common.…